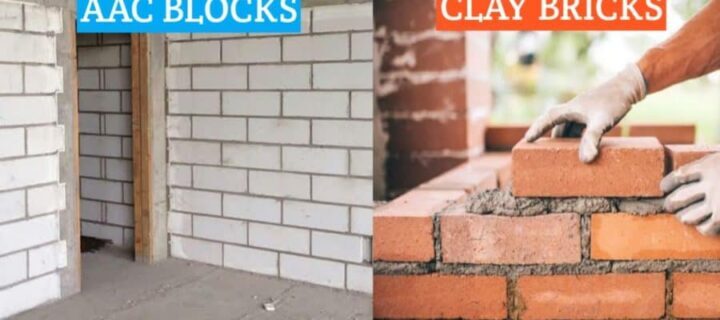

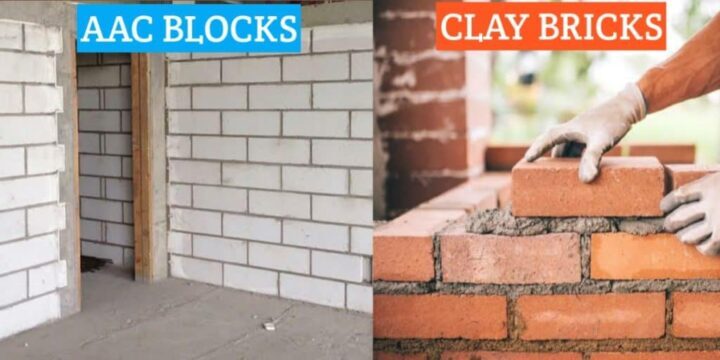

ACC BLOCK – MANUFACTURING AND COMPARISON WITH RED CLAY BRICK

This article explains the manufacturing process and a comparison on ACC Bricks vs Red clay bricks to make you get a clear understanding to choose between them.

ACC bricks was invented by Johan Axel Eriksson in the mid-1920s. He is a Swedish architect and inventor. Acc bricks is an important innovation of the 20th century in the field of construction. It is precast and lightweight building material that also provides safe structure, insulation, and fire and mold resistance. Acc Block is a unique type of construction materials due to its excellent heat, fire and sound resistance.

In AAC blocks prime ingredients are fly ash, cement, water, quicklime, aluminum powder, and gypsum. The cement strength provides hardness to block and instant curing mechanism by autoclaving. Gypsum provides long term strength to the block. The aluminum paste chemical reaction provides AAC its distinct porous structure, lightness, and insulation properties. The AAC blocks are 2.5 times lighter compared to conventional Bricks while providing similar strengths and specific gravity stays around 0.6 to 0.65. AAC blocks offer around 30 to 35 % saving of structural steel, and concrete, as these blocks reduce the dead load on the building significantly. It is a long run and durable material. it has been used in EUROPE over 90 years for commercial, industrial and residential application and the Middle East for the past 40 years and in America and Australia for 25 years. The report says that AAC now accounts for over 40% of all construction in the UK and more than 60% of construction in Germany. The Indian company has started production of AAC block in late 1972.

MARKET:

Fly ash is available in abundant quantity continuously and of good quality. The traditional manufacturers are showing a high willingness to use fly ash in their products. The current prices of ACC blocks are available in the same range of cement blocks & traditional bricks. But, as compared to traditional clay bricks the fly ash blocks are having more strength, fire resistance, earthquake resistance, lightweight, lesser breakage and saves structural cost by 40%.

It is a known fact that almost 60% of the country’s electricity comes from coal-based power station; the country has a huge stock of fly ash amounting to 60 million tons annually. But, fly ash reuse amount is not too encouraging as only 5% of the country’s total ash has been consumed in different sectors. With the rise in constructional activities and development of a country considering the improvement in the standard of living the demand for building bricks is increasing day by day.

RAW MATERIALS, SOURCES, AND AVAILABILITY:

Fly-Ash:

Fly is a star or major constituent of this product. Thermal Power plants use coal for power generation and fly is waste material of that process. Which is freely available to use. Moreover, the government has not applied any taxes on fly ash. The manufacturer has only to bear the transportation cost for fly ash supply.

Lime:

Active powered lime is required for giving aeration to the blocks. For the production of block, we can buy the active lime directly from the open market. Various qualities of lime are available in the market depending on the raw materials, the mix design can be chosen to get the optimal quality of production.

Ordinary Portland Cement (OPC):

OPC cement is used as a main binder material in the block. It is the main function is to provide early strength to block and also ensures a better cost effect effectiveness for the same. OPC is easily available in the local market is a major reason for using in block manufacturing.

Gypsum:

It is an industrial byproduct of Fertilizer Plant and also easily available material. Gypsum provides long term strength to blocks.

Aluminium powder :

It is used to make the lightweight product. Aluminum powder is added about 0.05 %, which is a too small amount. it reacts with silica and active lime base material to make the aeration, and swell the product, making it a very lightweight product.

Manufacturing Process of Acc Block:

Step: 1 Raw Material Preparation

1. COAL FLY ASH: Fly ash is filled in slurry preparing pond by wheel loader. Where fly ash slurry is prepared of concentration adding rated water, which will be pumped into slurry tank to be stored and ready to be used.

2. QUICK LIME: The active lime powder is stored in a lime silo and ready to be used by bucket elevator, after coming into the factory.

3. GYPSUM: It is stored in the upper shed will be added into slurry pond according to the required proportion, while preparing a slurry.

4. CEMENT: Cement is received by trucks and directly pumped into cement silo to be used.

5. ALUMINUM POWDER PASTE: The aluminum powder added to the mixer to prepare 5% suspending liquid to be used.

Step 2 – Dosing and Mixing:

It is the process of assuring the quality of the product by adding an accurate amount of raw material in mixer. Maintaining the ratio of all ingredients as –

FLY ASH OR SAND: LIME: CEMENT: GYPSUM = 69:20:8:3

· Aluminum is about 0.05% of total dry materials in the mix

· Water ratio = 0.60-0.65

· The cycle of mixing and pouring is 5.5 minutes.

For this mixing fly ash is filled in the container and as the desired weight is poured in, pumping is stopped. In a similar manner cement, lime powder and gypsum are poured into individual containers using conveyors. Once all materials are filled in their individual container in required amount system releases all ingredients into mixing drum. For aluminum powder feeding smaller bowl type structure is also attached as a part of the mixing unit. Once mixing of all material is done for a specified time, a mix is ready to pour in moulds. A dosing unit fills a set quantity of mix into each mould.

This process must be continuous without significant long time; otherwise, if there is a gap between charging and discharging of ingredients, the residual mixture might start hardening and choke up the entire unit. This process is completely automated and requires minimum human intervention.

Step 3 – Casting, Rising and Curing:

After the above raw material mix is ready to be poured is in moulds. AAC blocks moulds can be of various sizes depending upon installed capacity like 4.2m x 1.2m x 0.65m in size. Before pouring mould with the mix, moulds are coated with a thin layer of oil in order to ensure that green-cake does not stick to molds. As we pour slurry in mould, Aluminum reacts with Calcium Hydroxide and water and releases hydrogen gas. It leads to the formation of a small air pocket in the block. Air bubble size is about 2- 5mm. This is the major reason behind the lightweight and insulating properties of AAC block. After all this process is completed, the resulting product is to be cured for least 9 days after casting.

Step 4 – De-moulding and Cutting:

Once a block has achieved cutting strength, it is ready to be remolded and cut as per requirements.

AAC blocks are manufactured in long length strip during casting and then it is cut to required size and shape. Size and shape totally on market demand. Block cutting technologies also differ to machine unit provider.

ADVANTAGES OF AAC BLOCKS:

The advantages are as follows:

1. Fly is the main constituent in Acc Block manufacturing, which is a big problem for thermal power plants to dispose of. Reuse of fly is environment-friendly as no need to dispose of anywhere else.

2. Acc Block has better strength property, best thermal insulation & excellent sound absorption, vibration resistance compared to red bricks. The AAC blocks are lightweight offer easy and quick handling and transportation with lesser breakage.

3. Wall made with Acc Block can be left clean without plaster and gains strength over time. It helps in reducing structural cost by 35%.

4. There is no effect harsh climatic conditions on AAC blocks and will not degrade under normal atmospheric conditions.

5. It does not have any toxic substances nor does it emit odors. AAC block production, management, and disposal do not represent any health risks or damage to the environment. Its manufacturing process develops non-toxic gases.

6. Compare to conventional bricks, AAC block has bigger size resulting in a lesser number of joints. Less joint it means less use of mortar for wall construction.

To know more about ACC bricks in detail click here

Acc Block Vs Clay Bricks Comparison:

Property | Units | AAC Block | Clay Brick |

Size | mm | 600 x 200 x (75 to 300), | 230 x 75 x 115 |

Size Tolerance | mm | ± 1.5 | ± 05 to 15 |

Compressive Strength | N/mm2 | 3 – 4.5 (IS 2185 part 3) | 2.5 to 3.5 |

Normal Dry Density | Kg / m3 | 550 – 650 | 1800 |

Sound Reduction Index | Db | 45 for 200 mm Thick Wall | 50 for 230 mm Thick Wall |

Fire Resistance | Hrs. | 2 to 6 (Depending on Thickness) | 2 |

Thermal Conductivity “K” | W / m-k | 0.16 – 0.18 | 0.81 |

Drying Shrinkage | % | 0.04% (Size of block) | – |

Comparison Parameters:

Parameter | Acc Block | Clay Bricks |

Structural Cost | Steel Saving Upto 15% | No Saving |

Cement Mortar (plastering and masonry work) | Less Required due to flat, even surfaces & less number of joints | More required due to the irregular surface and the number of joints. |

Breakage | 5% less | 10 to 12 % Average |

Construction speed | Speedy construction due to its big size, lightweight & easy to cut in any size or shape | Comparatively slow |

Quality | Uniform & Consistent | Normally varies |

Chasing & Fitting | fitting and chasing possible | fitting and chasing possible |

Carpet Area | The thickness of walling material is less so more area available | Comparatively low |

Availability | Anytime | Shortage in monsoon |

Energy Saving | Approx. 30% reduction in air-conditioned load | No such saving |

Chemical Composition | Sand/Flyash used around 60 – 70 % which reacts with Lime & Cement to form AAC | Soil is used which contains many inorganic impurities like sulphates etc. resulting in efflorescence |

- ACC Block Price: Rs. 2000 to 3000 per Cubic meter or Rs. 30 to 40 per Block

- Red Clay Brick: Rs. 4 to 6 per Brick

Conclusion:

From the comparative study, it is acknowledged that the AAC blocks have a superior edge over burnt clay bricks. The AAC blocks use in building construction leads to savings in overall project cost; enables to speed up the construction process reduced environmental and social impact. Therefore we can say that AAC block use is a better choice for building construction compare to red burnt clay bricks. It is advisable to contractors, builders, and individuals to encourage this product as its use is in the national interest.

Join us in the ACC Bricks vs Red clay bricks debate in the comment section with your opinions and views.