How Much Does it cost for False Ceiling?

A false ceiling is an affordable way to enhance the look of your home. Find out how to calculate its actual cost and how much does it cost for false ceiling .

False ceilings have become a popular addition to Indian homes and can be installed in materials such as POP or factory-manufactured gypsum boards. This article will give you a fair idea about the costs of different types of false ceilings which include labour and material costs for fixing the POP or gypsum boards onto a framework of aluminium channels that are suspended from the true ceiling.

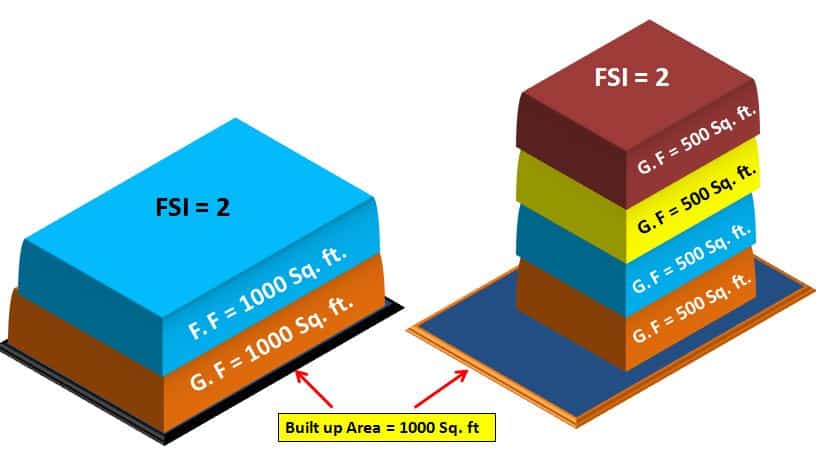

- Calculate the area of the false ceiling

- It is essential to calculate the area of the room or any other area of the home where the false ceiling needs to be installed. How? For example, if the bedroom is 12 feet long and 15 feet wide, then the area of the false ceiling for the bedroom will be 15×12 feet – that is, 180 square feet.

- Consider a cornice (at the junction of the false ceiling and the wall) along the perimeter of the room. The quantity and cost of the cornice is calculated on the basis of running feet.

- If you want to incorporate a tray or recessed light, like in this example, then measure the area of the tray light. This can be done by referring the dimensions of the tray light from the drawing of the false ceiling design. A 3–4-inch vertical section in POP or gypsum runs along the entire length of the tray light to hold the tube lights or LED strip lights within it. This section is measured in feet on the basis of its length.

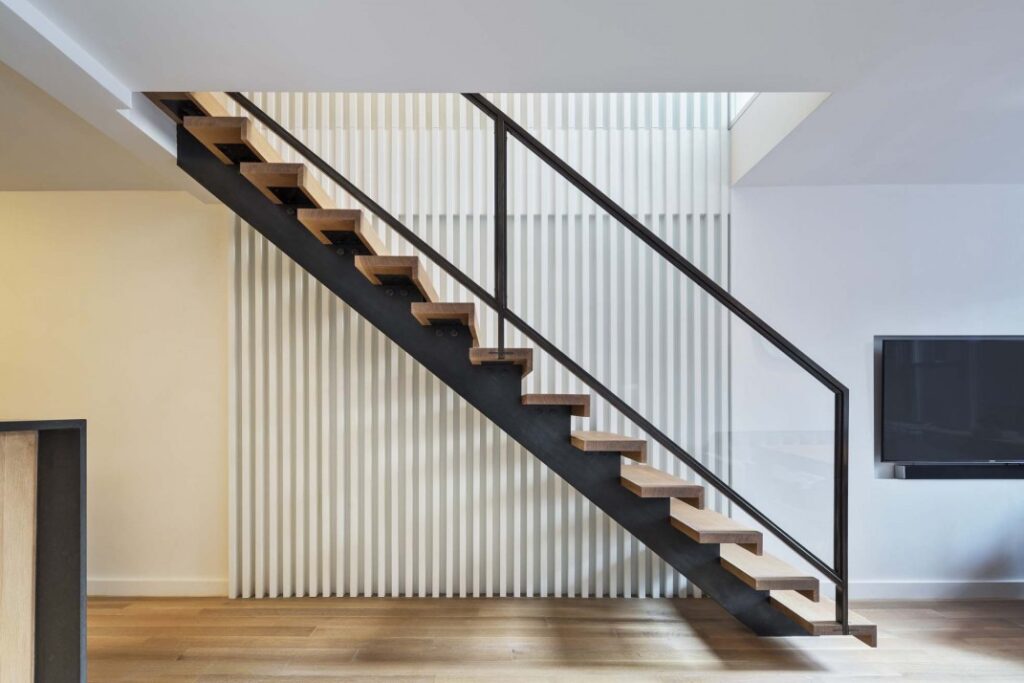

- Gypsum false ceiling

- Plain and simple straight-line gypsum false ceilings from reputed brands start at ₹75 per square foot.

- However, the the cost of the false ceiling can become expensive and go up to ₹125 per square foot if the false ceiling needs to be elaborately designed.

- POP ceiling

POP is available in the powdered form. It is mixed with water on site and can be moulded into any shape to achieve an ornamental design or an etched effect, such as you see in this example.

- POP ceilings can range between ₹75–120 per square foot, depending on the type of design details.

- POP cornices or decorative mouldings start at ₹45 per foot.

- Grid ceiling

These ceilings are made up of a grid of ceiling tiles in materials such as gypsum or metal. The standard size of the ceiling panels is 2X2 feet and they are available in a smooth, textured or patterned finishes.

- The cost of a grid ceiling starts at ₹75 per square foot, depending on the design of the ceiling tile.

- Metal ceiling tiles for a grid ceiling start at ₹90 per sq foot.

- Additional expenses

The additional expenses involved during the installation of a false ceiling include:

- The electrical wiring that runs just above the false ceiling.

- Fixtures such as concealed lights, LED strip lights and chandeliers, which need to be purchased separately.

- The cutting of the gypsum or POP ceiling for installing the concealed light fixtures. The contractors will charge extra for this, as per the layout of the false ceiling.

- The finishing of the false ceiling with paint, textured paint or wall paper.

- Pairing gypsum with other popular false ceiling materials such as plywood, glass and acrylic raises the style quotient, but at an additional cost.

This is the approximate cost for false ceiling .

Read More :

Reasons to Install False Ceiling in your Home

How Much Does it cost for False Ceiling? Read More »