Grade of Concrete – Their Ratio,Uses and Suitability

Grade of Concrete – Their Ratio,Uses and Suitability Read More »

Grade of Concrete is the classification of concrete according to its compressive strength.

For making concrete we use cement, sand, aggregate, and water which are mixed with certain ratio and concrete is cast and put in a cube of 150 mm size and put in a water bath for 28 days and afterward, it is tested in a compression test. The compressive stress result is known as “grade of concrete’. It is expressed in N/mm²

Concrete grades are denoted by M10, M20, M30 and so on according to their compressive strength.

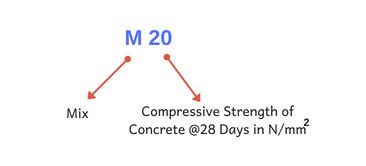

The “M” refers Mix and Number after M (M10, M20) Indicates the compressive strength of concrete after 28 days of curing and testing.

M indicates the proportion of materials like Cement: Sand: Aggregate (1:2:4) or Cement: Fine Aggregate: Coarse Aggregate.

If we mention M10 concrete, it means that the concrete has 10 N/mm2 characteristic compressive strength at 28 days.

In the designation of concrete mix M to the mix and the number to the specified compressive strength of 150 mm size cube at 28 days, expressed in N/mm^2.

As per BS 8500-2 British/European standards The grade of concrete is denoted as C10, C15, C20, C25, etc., ‘C’ which means ‘Concrete Strength class’ and number behind C refers to characteristic Compressive strength of Concrete in N/mm2 @ 28 days when tested with the 15 cm dia. & 30 cm height cylinder in a direct compression test.

The grade of concrete is also denoted as C16/20, C20/25, C25/30, etc., which means Concrete Strength Class (C) the number behind C refers to Compressive strength of Concrete in N/mm2 when tested with Cylinder / Cube.

Different mix proportions of the materials used to make concrete namely

Result in concretes with different properties.

Grades of Concrete | Mix Ratio (cement : sand : aggregates) | Compressive Strength | psi |

Grades of Concrete |

|

| |

M5 | 1 : 5 :10 | 5 MPa | 725 psi |

M7.5 | 1 : 4 : 8 | 7.5 MPa | 1087 psi |

M10 | 1 : 3 : 6 | 10 MPa | 1450 psi |

M15 | 1 : 2 : 4 | 15 MPa | 2175 psi |

M20 | 1 : 1.5 : 3 | 20 MPa | 2900 psi |

Standard Grade of Concrete |

|

| |

M25 | 1 : 1 : 2 | 25 MPa | 3625 psi |

M30 | Design Mix | 30 MPa | 4350 psi |

M35 | Design Mix | 35 MPa | 5075 psi |

M40 | Design Mix | 40 MPa | 5800 psi |

M45 | Design Mix | 45 MPa | 6525 psi |

High Strength Concrete Grades |

|

| |

M50 | Design Mix | 50 MPa | 7250 psi |

M55 | Design Mix | 55 MPa | 7975 psi |

M60 | Design Mix | 60 MPa | 8700 psi |

M65 | Design Mix | 65 MPa | 9425 psi |

M70 | Design Mix | 70 MPa | 10150 psi |

Concrete Grade N/mm2 | Ratio Cement, Sand and Aggregates | Usage |

10 | 1:3:6 | Blinding concrete |

15 | 1:2:4 | Mass concrete |

20 | 1:1.5:3 | Light reinforced concrete |

25 | 1:1:2 | Reinforced concrete/precast |

30 | Concrete Mix Design | Heavy Reinforced concrete/pre-cast |

35 | Concrete Mix Design | Pre-stressed/pre=cast concrete |

45 | Concrete Mix Design | Very heavy reinforced concrete/pre-cast/prestressed |

Grade of Concrete – Their Ratio,Uses and Suitability Read More »

As we decide to build a new home, there are many question and queries comes in mind. House construction is not a temporary structure. we want to build a house that can last long for a too long period. for that we choose to use the best practices, materials, and methods of construction.

To satisfy this requirement we look for,

Which is the best cement for the house?

Which is the best grade of concrete?

Which is the best flooring material?

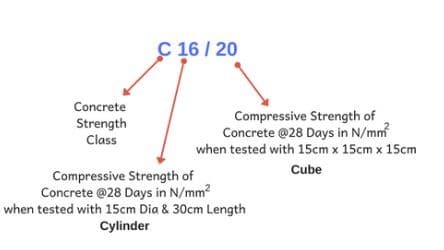

Which is the best brick for house construction?

There are too many things we are looking for. so in this article, we will try to give you an answer to the question that is which is the best brick for house construction.

As we know there are two popular bricks available in the market one is fly ash bricks and other is red clay bricks. We will do some comparative study on fly ash vs clay bricks to decide which is best for house construction.

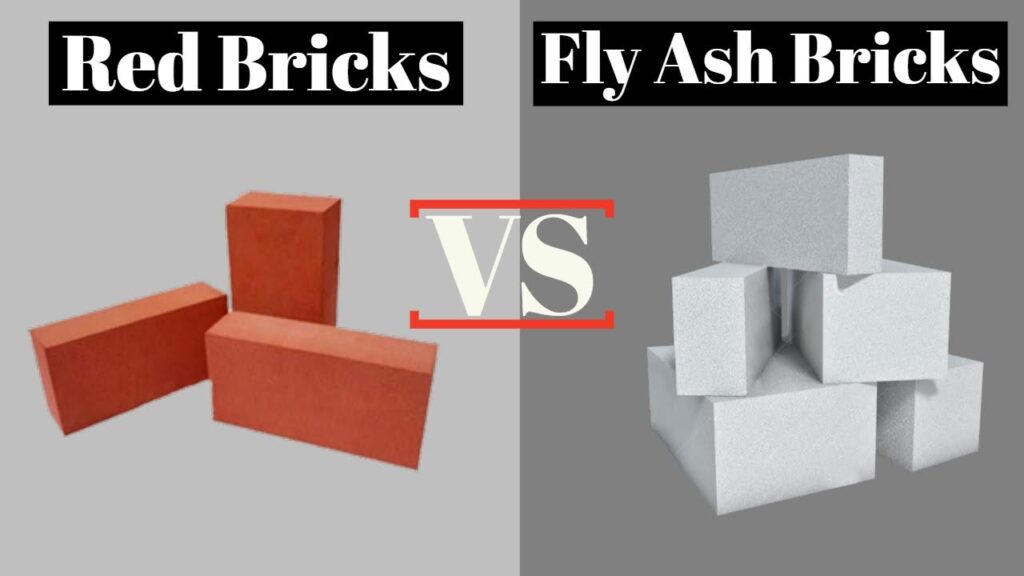

Fly Ash Bricks | Red Clay Bricks |

These Bricks are made from cement, slag, fly ash. | Red Bricks are manufactured form Clay Soil |

Fly Ash Bricks | Red Clay Bricks |

Fly ash brick has more uniform shape as they are cast in machine mould | Red bricks do not have uniform shape as they are hand mould made |

Fly Ash Bricks | Red Clay Bricks |

Fly ash brick has Cement grey color | Red brick has color red to light brown |

Fly Ash Bricks | Red Clay Bricks |

Fly Ash Bricks has compressive strength – 75 to 100 kg/cm² | Red Brick has compressive strength – 30 to 35 kg/cm² |

Fly Ash Bricks | Red Clay Bricks |

Fly Ash Bricks wastage on site is around | Red Brick wastage on site is more than |

Fly Ash Bricks | Red Clay Bricks |

Fly Ash Bricks has Water Absorption of about 6 -12 % | Red Brick has Water Absorption of about 20 – 25 % |

Fly Ash Bricks | Red Clay Bricks |

Fly Ash Bricks Weight is 2.6 kg | Red Brick Weight is 3.5 kg |

Fly Ash Bricks | Red Clay Bricks |

Fly Ash Bricks Cost is about Rs. 4 to 6 | Red Brick Cost is about Rs. 5 to 8 |

From the comparison, anyone can clearly predict that Fly Ash Bricks has more advantages than clay bricks for new house construction.

Advantages of Fly Ash Bricks over Clay Bricks

In all aspects fly, ash bricks are better than clay bricks. They are environment-friendly because maximum constituent is ash and fly ash bricks has greater strength as compared to red bricks.

This is our comparison of fly ash vs clay bricks. Do join us in our fly ash vs clay bricks debate in the comment section by giving your opinions and views.

Read More :

ACC Bricks VS Red Clay Bricks : A Comparison

Top 10 Innovative Construction Materials

Fly Ash vs Clay Bricks : A Comparison Read More »

Building a construction step involve in any type of construction is not an easy task; perhaps it requires lots of afford and investment. Although, for building construction requires lots of time and it is tedious work, yet its result is a permanent asset for us. Therefore, care should be taken in building construction process. Before planning, building construction projects must consider important aspects like the purpose of construction, utility, financial proficiency, the demand for work, etc.

As the decision of building construction taken, the planning phase is started. First of all start with some preconstruction steps.

Following are the building construction steps:

II) During Building Construction Steps:

The following are the building construction steps.

It is the most important step in building construction. Search for the location for the building which is best suited for building construction purposes. Be careful while selecting land which has all the desired facilities available nearby and should be free from all land-related issues. It is suggested that do prior data collection before buying land or plot either by doing research online or seek help from real estate agents or concerned persons regarding the effective cost of the same.

After selecting proper land for building, take the help of a professional architect to create building designs and take his/her advice. An architect prepare plan as per building requirement, number of flats, shops based on your requirements and budget. Then after architect consult with a structural engineer for details of the reinforcements to be used, how deep your foundation will be, the size of gravel to be used, pillar width, etc.

Building construction involves a huge amount of material and budget. After, planning and structural detailing completed these details are transferred to the building estimator. The building estimator will estimate the material quantity, quantity of different items of work, and prepare an abstract sheet that shows the cost of building construction. If financial resources are limited, we need to seek pre-approval for loans in advance or else you may end up in a cash crunch situation.

This is important work to do after the project is ready to be executed. For that, we have to take permission from the local municipal body before you could go for the construction.

Following are the list of document project required before applying for permission. This document may differ from state to state, but some are essential for every building construction work.

a) Land survey: Survey of the land has to be carried out with the help of authorized land surveyor

b) Soil test report of the land.

c) Land documents.

d) Architecture/ elevation/ sectional drawings.

e) Structural report.

f) Architect Certificate of undertaking on Record and Certificate of the undertaking of Civil Engineer on Record

A builder or contractor for construction must be chosen carefully because it is a major factor for securing building construction quality and timely construction of work. Pre investigation must be done about the builder before handing work. In the contract document, all the work-related details must be clearly stated. The contract document should cover layout and work details along with the payment methods, time scales and costs. The condition of the contract should be thoroughly checked before signing a final deal.

The following are the building construction step involves for any type of construction.

The construction site must be cleaned before the work is executed. This work involves the removal of roots of trees, debris and leveling ground area.

The foundation of building ground is excavated with the help of excavating machines as per the building dimension specified in drawings. In this foundation trench, a layer of PCC (Plain cement concrete) is laid in the dug portion before placing the reinforcements for the foundation.

The building is supported on the foundation is the lowermost part of the building that is in contact with the soil. A building is load transferred from the superstructure to the soil and needs to be extremely strong to handle the load. After the PCC work foundation reinforcement work is started. The foundation bottom level must check before concreting it. The remaining space between the foundation is filled with earth.

After the foundation work is done ground beam formwork preparation is started and poured with concrete. Over the plinth beam, masonry work is started. And space between foundation and plinth beam filled with soil.

The superstructure is the portion above the plinth level of the building. The main component of the superstructure is a column and beam. The columns are built up to slab level and the frame for further construction is prepared.

As column and beam framework completed masonry work is started with different materials such as bricks, concrete blocks, fly ash bricks, etc. according to building drawing. Masonry work is done using a cement mortar mix. It is a mixture of cement & sand. During this carefully and as per drawing gaps are laid for doors and windows during the masonry work.

The lintel is constructed on the door and window to support the masonry work over it. After this further masonry work is done.

Then the formwork is started to construct slab resting on the column and beam. Over slab formwork, slab reinforcement is placed as per slab detailed drawing.

After that door window frames are fixed at their specified position given in drawing.

As we know that buildings are constructed with a clean finish in which electrical and plumbing work is not visible. They are installed in the walls and slabs such that they are concealed and not visible after the finishing work is done. The point and pipe end left out such that later they can be finished with the electric fitting and plumbing fixtures.

Once this work is completed, external plastering and finishing work is started. Waterproofing is also done to prevent rising dampness in the wall. External cladding can also be done to enhance the elevation of the house.

On top of the slab, waterproofing is done to prevent any leakage in the slab. Generally, terrazzo tiling is done to prevent the slab from a weathering effect.

Internal walls are plaster with smooth finish and flooring is done with tiles. Later on, the walls are painted or textured.

By following the above step, almost construction work is completed and then after furniture work is started. Side by side, electrical fitting, switchboard, and plumbing fittings are complete in the bathrooms and kitchen areas too.

The last step of building construction is interior decoration work in completing the building construction with proper furnishing and fabric used.

Step by Step Process of Building Construction Read More »

What is the construction cost per sq.ft ? When you think about constructing a new house and you are searching for the right contractor this term must be heard by you. The Construction cost per sq.ft for a residential house depends upon on a lot of factors. We can say that the cost to depend upon the following factors:-

1) Purpose of construction of the house: – The Cost of Construction for a rental house construction may low, whereas a standard house for personal use will start from high price level.

2) Type of Internal finishing expected:-The Quality of painting, woodwork, Bathroom Fittings, flooring, Electrical fittings, etc. you use will affect the cost.

3) The type of Exterior Finish:- If you want good front elevation design, you have to pay higher construction cost like stone cladding or Extensive Grillwork, etc.

4) Total built up area:- The wider the area and more the no. of floors, lower the price for construction for the same type of features.

5) Location of Land:- If you are constructing a house in a remote area, where construction material and Labour are not easily available. The cost of construction much higher than in other areas.

Following are some value of the cost of construction in various countries and major cities of the world.

The cost of construction in various cities of at a $ 200, though national average stands at $ 250.

RESIDENTIAL:

Single Family Detached-Medium Quality – 150 to 400 $ per square foot.

Apartment/Condominium-Mid Rise – 200 to 500 $ per square foot.

This figure varies in various cities of united states like San Francisco, Los Angeles, San Diego, Las Vegas, etc.

Construction cost per square feet

Generally, for Constructing new homes in London several factors affect the cost and therefore a minimum of £2,000 per square meter (£185 per square foot) may be a more realistic estimate.

When it comes to the average cost of construction to build a house in Canada, according to Home Builder Canada, the price per square foot for a detached home in major Canadian cities is as follows:

Vancouver: $130 – $230

Constructing a new house in Australia is not easy for the lower class resident. If we consider Site Costs $10,000 – $70,000, Basic cost – $10,000 Driveways and Flooring – $10,000. So it would generally need to add around $40,000 or more to the cost of the build in extra costs.

The cheapest house you can construct in Australia is somewhere around $155,000.

1) Project Homes (basic) – $620-$780/square meter

2) Project Home (deluxe) – $1,000 – $3,000/square meter

3) Custom Built Homes – $1,500 – $3,000/square meter

Cost range per floor area ($/m2)

Sydney $1,780 Melbourne $1,720

Adelaide $1,580 Brisbane $1,800

If we consider average, the construction cost per sq.ft in India would range between Rs.1200 to Rs.1800/-.

This range may vary from city to city like Mumbai, Kolkata, Bangalore, etc.

Read more :

The Market Price of Construction and Building Materials

List of Top Innovative Construction Materials

Construction Cost per Sq.ft : Cost around the World Read More »

A list of Construction and Building materials price is required before starting any construction project whether it is a home, industrial or commercial purpose. In building construction, we used lots of different types of construction materials, finishing, protective and decorative materials. But, some materials are essential without that construction work may not be complete such materials list includes cement, steel, sand, ready mix concrete, binding wires, coarse aggregates, fine aggregates, bricks, blocks, etc. The used construction materials have to be selected carefully to ensure the safety and long-lasting life of the building.

All the Building materials available in various grades, Sizes and Brands which are used for different purposes in construction based on their functionality and strength.

Following is the building material list required for any construction work.

Portland cement is the basic and most essential ingredient of concrete. Concrete is made when Portland cement creates a paste with water that binds with sand and rock to harden. Cement is a material like the glue that can bind together all other building materials and get harden too. The cement is available in different like, 53 grades, 43-grade cement, OPC (ordinary Portland cement), PPC (Portland pozzolana cement), etc. It is the most expensive construction materials

Cement Price: 4 to 5 dollars per 50 kg bag or 300 to 350 Rs. Per 50 kg bag.

TMT bars or Thermo-Mechanically Treated bars are high-strength reinforcement bars having a tough outer core and a soft inner core. Steel is a high-strength material compared to concrete. The reinforcing steel is strong in tension as well in compression. It plays an important role in giving strength to structure in the construction projects.

TMT steel bars are available in Fe 500 grade, Fe 500 D grade and Fe 550 grade which signifies the strength of the steel.

TMT/TMX Price: 45 to 60 Rs. Per Kg or 0.75 to 1 $ per Kg.

Sand is a naturally-occurring material consisting of very small, loose particles of decomposed rocks, corals, or shells. Sand is used to strength, bulk and other properties to construction materials like asphalt and concrete. Sand is also used as a decorative material in landscaping. Some types of sand are used in the manufacture of glass and as a molding material for metal casting.

Generally, sand is extracted from the river bed and cleaned to be used construction. There is also available manufactured sand also well-known as the M-sand is gaining popularity due to the recommendation from the government and its fineness and dust-free quality.

Sand Price: 1500 to 3000 Rs. Per Tonne.

Ready-mix concrete is the plant manufactured and directly delivered at the construction site. It is preferred when a workspace is limited on construction site and making concrete on site is too difficult tasks. Some time Ready Mix Concrete used because the quality of concrete is more important.

As per the requirement and use RMC is categorized into M-20, M-25, M-30, M-35, etc.

RMC Price: 3000 to 7500 Rs. As per grade of Concrete.

Binding wires are the thin iron steel wire that used to bind or tight the TMT Steel bars and help in providing proper structure to the construction due to the stability of the TMT Steel Bars. Approximately, 1 tone of steelwork on-site consumes 8 to 10 kg of binding wires.

TMT Binding Wires Price: 40 to 50 Rs. per Kg.

Coarse aggregate extracted by breaking from rocks using explosives & crushed into pieces using machines & coarse aggregate sizes 6mm, 12mm, 20mm, 40mm, 60mm is divided using big sieves in machines & coarse aggregate like 6,12,20mm is used to mix in concrete for construction purposes & 40mm is used for railroads. The coarse aggregate provides the main structure to the concrete and load-bearing ingredient of the concrete.

Coarse Aggregates Price: 60 to 70 Rs. per Cubic Feet.

Bricks and Blocks are mainly used for building walls. Bricks come in various shapes, sizes, and strengths-based on different construction requirements. Nowadays, Light Weight Fly ash concrete block for the wall, parapet, and boundary wall construction. They are light in weight compared to conventional bricks.

Bricks: 6 to 10 Rs. per Piece.

Light Weight Blocks: 40 to 50 Rs. per Piece.

The Market Price of Construction and Building Materials Read More »

Introduction:

Stairs is a set of numbers of the stair which provide easy traveling from floor to floor. The room or space between which a stair is located is known as the staircase. The staircase provides access & communication between floors in multi-story buildings. They are the path by which fire can spread from one floor to another.

Therefore it must be enclosed by fire-resisting walls,¢ floors, ceilings, and doors. It must be designed to carry certain loads, which are similar to those used for the design of the floors. For the construction of stair various materials can be used like Timber, Bricks, Stone, Steel or Reinforced Cement Concrete.Let us look in detail about the staircase calculation.

STEP: – It is a portion of the stair which provides upward or downloads movement. A stair is composed of a set of steps.

TREAD: – It is a top portion or surface of step on which foot of ascender or descender comes when going up or download by stair.

RISER: – It is a vertical portion of a step providing support to the tread.

LANDING: – It is a level platform at the top or¢ bottom of a flight between the floors.

RISE:– A vertical Space between the top of lower tread and bottom of upper tread faces.

NOSING:- It is the projected portion of a tread beyond the face of the riser.

SCOTIA:- It is a moulding provided under the nosing to provide strength to the nosing.

SOFFIT:- it is a portion which is the underside of stair.

PITCH OR SLOPE:- It is the angle which the line of the nosing of the stair makes with the horizontal.

FLIGHT:- This is an unbroken series of steps between landings.

STRINGS OR STRINGERS: – These are the slopping members who support the steps in a stair.

NEWEL POST: – It is Vertical member of the stair which is located at end to each flight to connect the ends of strings and handrail.

BALUSTER: – It is a safety member of the stair which is made of wood or metal, supporting the handrail.

HEADROOM: – It is the clear vertical distances¢ between the tread and overload structure.

Before starting please make the below assumptions

(Note – This is not a fixed rule, according to the type of building, use of the building and many other factors affect the size of the rise and tread for stair.)

For Example, in hospitals, the rise maybe 5″ because the staircase mostly utilized only by the ill or sick people where they have to climb without using their full energy. So the riser may be shortened for easy access. The tread also should be wider enough.

The reason we are providing 10” inches for tread is every person will wear a slipper which may be maximum 10” for an average adult person based on that we are making tread space as 10” inches minimum.

The following are some pointers to be considered while planning a staircase:

• The respective dimensions of tread and riser for all the parallel steps should be the same in the consecutive floor of a building.

• The minimum vertical space or headroom above any step or the stair should be 2 m.

• Generally, the number of risers in a flight should be restricted to 12.

• The width of the stair should not be less than 850 mm. The standard width of any stair may be between 1.1 to 1.6 m. In public use building like malls, cinema, shopping center larger width of stair can be used.

While planning any stair important dimension to find out first that is rise and tread of stair and their numbers.

Before finding out rise and thread fix following points,

Total Clear Distance Between two-floor (A) = 10’6” (3.20m)

Total Width of one flight or Distance between the first riser to last riser (B) = 1.80m

First of all decide size of riser,

Riser Size = 7” (inch) (Range of riser = 6”to 8”)

Nos. of Riser = Clear Distance between two floors (A) / Size of Riser

= (10’6”/ 7”)

= 18 nos. (9 for first flight and 9 for second flight)

Now, we will calculate the size of tread,

(We know that for any stair numbers of tread for any single flight are one less than several rises.)

Number of threads on single flight = Nos. of Rising of single flight – 1

= 9 – 1

= 8 nos.

So, Size of Tread = Total width of Stair / Nos. of Thread

= 6’ (72”) / 8

Size of Tread = 9”

(This dimension can be changed as per types of the stair)

Final Data:

1) Size of Rise = 7”

2) Number of Riser on single flight = 9 nos.

3) Width of Tread = 9”

4) Number of Tread = 8 nos.

This is the detailed Staircase calculation .Let us know for any of your doubts in Staircase calculation in the comment section below.

Read More :

How to do Staircase Calculation ? Read More »