GRADE OF CONCRETE – THEIR RATIO, USES & SUITABILITY

Grade of Concrete is the classification of concrete according to its compressive strength.

For making concrete we use cement, sand, aggregate, and water which are mixed with certain ratio and concrete is cast and put in a cube of 150 mm size and put in a water bath for 28 days and afterward, it is tested in a compression test. The compressive stress result is known as “grade of concrete’. It is expressed in N/mm²

Concrete grades are denoted by M10, M20, M30 and so on according to their compressive strength.

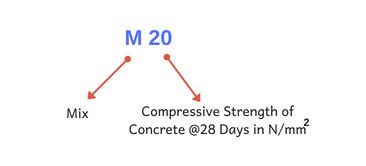

As Per Indian Standards:

The “M” refers Mix and Number after M (M10, M20) Indicates the compressive strength of concrete after 28 days of curing and testing.

M indicates the proportion of materials like Cement: Sand: Aggregate (1:2:4) or Cement: Fine Aggregate: Coarse Aggregate.

If we mention M10 concrete, it means that the concrete has 10 N/mm2 characteristic compressive strength at 28 days.

In the designation of concrete mix M to the mix and the number to the specified compressive strength of 150 mm size cube at 28 days, expressed in N/mm^2.

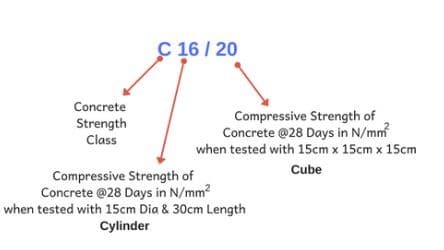

Grade of Concrete as Per British/European standards:

As per BS 8500-2 British/European standards The grade of concrete is denoted as C10, C15, C20, C25, etc., ‘C’ which means ‘Concrete Strength class’ and number behind C refers to characteristic Compressive strength of Concrete in N/mm2 @ 28 days when tested with the 15 cm dia. & 30 cm height cylinder in a direct compression test.

The grade of concrete is also denoted as C16/20, C20/25, C25/30, etc., which means Concrete Strength Class (C) the number behind C refers to Compressive strength of Concrete in N/mm2 when tested with Cylinder / Cube.

Different mix proportions of the materials used to make concrete namely

- Cement

- Coarse aggregate

- Fine aggregate

- Water

Result in concretes with different properties.

Following are the standard concrete grade with their mix proportions and strength.

Grades of Concrete | Mix Ratio (cement : sand : aggregates) | Compressive Strength | psi |

Grades of Concrete |

|

| |

M5 | 1 : 5 :10 | 5 MPa | 725 psi |

M7.5 | 1 : 4 : 8 | 7.5 MPa | 1087 psi |

M10 | 1 : 3 : 6 | 10 MPa | 1450 psi |

M15 | 1 : 2 : 4 | 15 MPa | 2175 psi |

M20 | 1 : 1.5 : 3 | 20 MPa | 2900 psi |

Standard Grade of Concrete |

|

| |

M25 | 1 : 1 : 2 | 25 MPa | 3625 psi |

M30 | Design Mix | 30 MPa | 4350 psi |

M35 | Design Mix | 35 MPa | 5075 psi |

M40 | Design Mix | 40 MPa | 5800 psi |

M45 | Design Mix | 45 MPa | 6525 psi |

High Strength Concrete Grades |

|

| |

M50 | Design Mix | 50 MPa | 7250 psi |

M55 | Design Mix | 55 MPa | 7975 psi |

M60 | Design Mix | 60 MPa | 8700 psi |

M65 | Design Mix | 65 MPa | 9425 psi |

M70 | Design Mix | 70 MPa | 10150 psi |

The selection of the concrete grade depends on the situation and uses:

Concrete Grade N/mm2 | Ratio Cement, Sand and Aggregates | Usage |

10 | 1:3:6 | Blinding concrete |

15 | 1:2:4 | Mass concrete |

20 | 1:1.5:3 | Light reinforced concrete |

25 | 1:1:2 | Reinforced concrete/precast |

30 | Concrete Mix Design | Heavy Reinforced concrete/pre-cast |

35 | Concrete Mix Design | Pre-stressed/pre=cast concrete |

45 | Concrete Mix Design | Very heavy reinforced concrete/pre-cast/prestressed |